Because aesthetics only is not always enough.

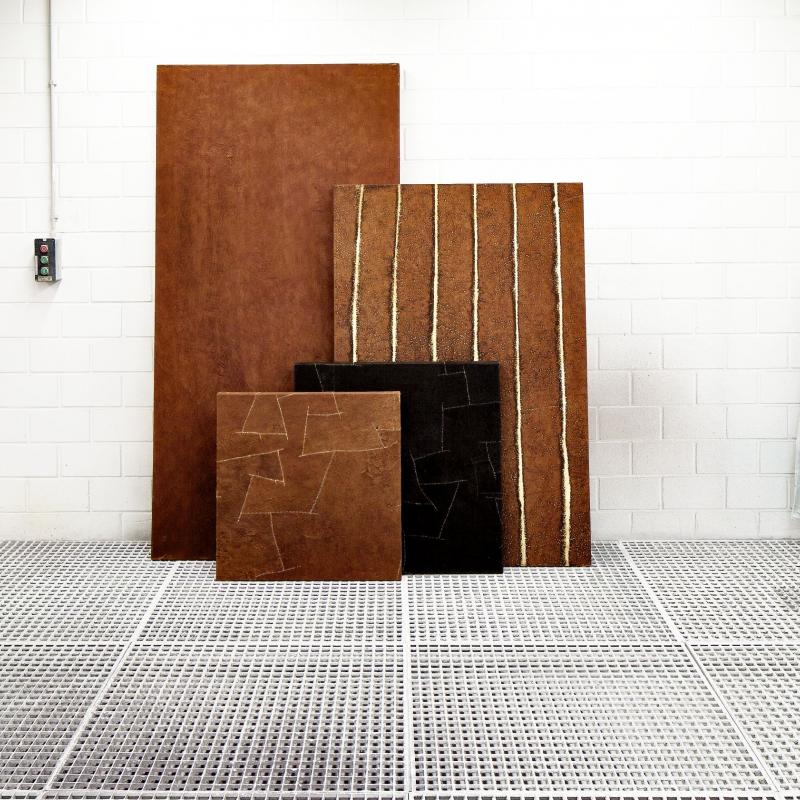

BARKTEX®_functionals is made from BARKTEX®_aesthetics or the traditionally made BARK CLOTH, in order to meet modern requirements on functionality for various applications.

BARKTEX®_Fire-resistant_0533

Fire resistant finishing according to the latest EU requirements EU standard DIN EN 13823, partly identical with the "old" German industrial standard DIN 4102 B1. Available for BARK CLOTH and most types of BARKTEX®_aesthetics.

BARKTEX®_Acoustics_0100

Individual solutions in sound absorption. Are you also sick of those eternal perforated or slit boards? Hungry for going new paths? What about the world's largest sound absorbing solution with a surface free of pattern repeats? We can offer these with at least 5 000 x 15 000 cm free of fouls, with no rapport. One has to first come up with this idea.

BARKTEX®_Laminated_055x

Available on a wide selection of fabric- or synthetic laminated BARK CLOTH or BARKTEX®_aesthetic products. Increases tensile strength and for some applications simplifies the workability. It is also useful if the backside should be visible in another look. Laminated bark products are used in the various sectors. The applicability of laminating materials with different properties depends on the intended use. The most commonly used materials are cotton fabrics and PE fleece. Silk adds class and gracefulness. Awarded a Certificate of Excellence from Material ConneXion, New York. Contact us if you wish to use non-flexible materials such as wood products/veneers or between or under/over glass or PETG/PMMA. For special requirements we can arrange contact with experienced finishing specialists.

BARKTEX®_Stainguard_0511

Stain protection finishing. Water and oil repellency, and resistance to general dry soiling. Available for BARK CLOTH and most BARKTEX®_aesthetic products. Like many other wooden materials, also tree bark fleece offers antimicrobiotic and cytotoxic properties. Therefore, they are generally less prone to staining than e.g., cotton or most synthetics. For this reason, we do not recommend a stain protection finish for all purposes.

BARKTEX®_Softgrip_0517

The tree bark fleece for softies. Increased skin sympathy, voluminous touch effect, as well as significantly increased suppleness and elasticity is provided by a softening finishing process. Feels a bit artificial, you might still remember these babyfeel-grip added textiles from your childhood . Can be used for clothing, but is only required for exceptional purposes. Available for BARK CLOTH and most BARKTEX®_aesthetic products.